When it comes to cargo securement in a pickup truck bed, pickup trailer, moving van, or professional trucking trailer having a good securement following proper securement practices is critical. Today we will be going over some of the best ways to secure cargo using tie-down straps to make sure the cargo you are securing is being done safely and correctly.

Today we will be going over some of the best ways to secure cargo with a tie-down strap to make sure the cargo your are securing is being done correctly. This blog post today was created using Canada Cargo’s tie down securement experts combined years of professional shipping experience.

What Tie Down Straps Work Best For Cargo Securement?

When it comes to finding out the best tie-down straps that work for your application the first thing you will need to consider is the size, shape, and weight of your load. Cargo can come in all shapes, sizes, weights, and securement challenges along the way but the most common things you will need to know when picking the right strap is the weight of the cargo and the length of tie-down webbing you will need for your application.

If you need help finding the length of webbing you need a quick do it yourself tip is to take a piece of yarn or string and go around your cargo until it is secured on each side and measure it after. This takes away some of the guesswork that your strap could be too short or too long. Now that you know the length of tie down webbing that you need for your application you will need to pair the length with the weight of the strap in kgs or lbs. If your cargo totals 10,000 lbs, for example, you need to find four straps with AT LEAST 10,000 lbs or greater working load limit combined. However, you will always want to allow yourself more wiggle room in case a strap were to break that you would be okay.

Once you have determined the Safe Working Load Limit for your load you will need to determine the width of the strap you need. If you have pickup trailer or moving van applications can normally get away with 1-inch Tie Down Straps or 2 inches Tie Down Straps in the majority of cases. Flatbed Trailers will often use 2 inches, 3 inches, or 4 inches Tie Down Straps as industry-standard practices.

What Hardware Do I Need for my Tie Down Straps?

Depending on the type of cargo securement you are using such as E Track Rails along the walls or flooring of a trailer or moving van or if you are using straps in a pickup trailer this can greatly vary. Straps such as Cam Buckle Straps, Ratchet Straps, E Track Straps, and Winch Straps are the most popular types of tie-down straps that are used for cargo securement for most users. If you are looking at bundling cargo, goods, or cargo to a pallet you will want to use straps such as Endless Loop Tie Downs.

Tie Down Hardware can range from Hooks, E Track Fittings, Cam Buckles, and a very wide range of different cargo securement options. If you don’t see exactly what you are looking for in our online store chances are we could custom make to order the perfect strap for you. Give our experts a call 800-265-0823 or by using our online contact us form here.

How to Tighten a Ratchet Strap Step by Step

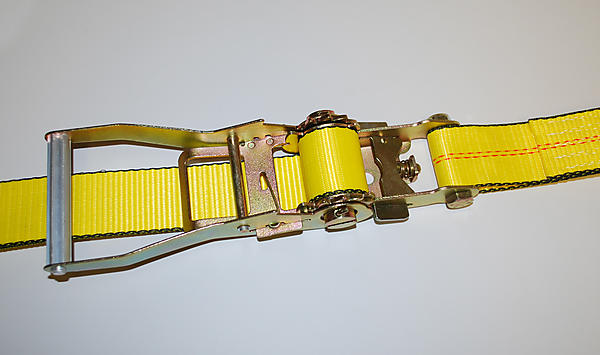

1). Start off by threading the Ratchet Strap webbing through the ratchet hardware.

2). Next, pull the slack through the Ratchet Hardware to get rid of the excess slack or excess webbing.

3). Make sure there is tension on the excess webbing being pulled away from the ratchet to prevent knots or the webbing becoming tangled or jammed.

4). Start Ratcheting until the tie down webbing is firm but do not overtighten the ratchet as it could cause damage to the cargo.

5). Once the ratchet has reached the desired tightness for your cargo securement remember to make sure to have the ratchet handle completely closed in order to prevent the cargo from becoming unsecured.

How to Release a Ratchet Strap Instructions

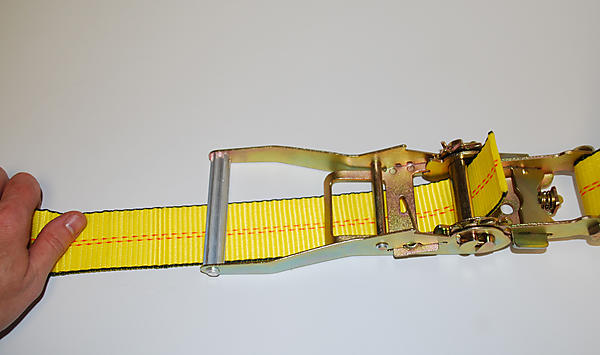

1). In order to release the Ratchet Start by opening the Ratchet Handle until the Ratchet is flat. This will start to release the tension on the Ratchet Strap.

2). Next, Pull the webbing out from the opposite side of the Ratchet Hardware that you secured the cargo on by pulling.

3). You will notice the tie-down webbing come completely out of the Ratchet Hardware, this is exactly what you will want to see if you are doing this step correctly.

4). Lastly, remember that when you are completely done using the strap to store the tie-down strap properly by keeping it out of direct sunlight, damp areas, and make sure the strap is rolled up to prevent fraying of the tie-down webbing.

Differences between Polyester Tie Down Webbing & Nylon Webbing Blends

There are two main types of webbing in the tie-down securement industry with one being Polyester and the other being Nylon. The main difference between the two is one stretches very little and one stretches very much. Polyester Tie Down Webbing is used for securement applications such as inside the back of a pickup truck, cargo van, flatbed, treestand, ATV securement, Motorcycle securement, and the Automotive industry just to name a few.

Nylon Tie Down Webbing is used in applications such as vehicle recovery from deep snow, mud, fields that are being farmed, water, and other obstacles that need recovery. The reason you want this webbing to stretch is to help reduce the strain on the vehicle from becoming damaged from a sudden jolt movement that could easily break a tow hitch, body panel, or rim if you were to use polyester tie down webbing for towing applications.